All our safety and isolation transformers are made to order with the characteristics and values of primary and secondary voltage indicated by the individual Customers. Over the years O.C.E. has developed several characteristics in order to improve product quality and customer satisfaction. On each transformer it is possible to choose various features to make the product closer to the needs of the installer and the designer.

Custom-made

A careful assessment of our customers’ needs has allowed us to develop a specific customization method that allows us to reduce delivery times for custom-made safety and insulation transformers.

Below we list some of the features that O.C.E. can offer its customers:

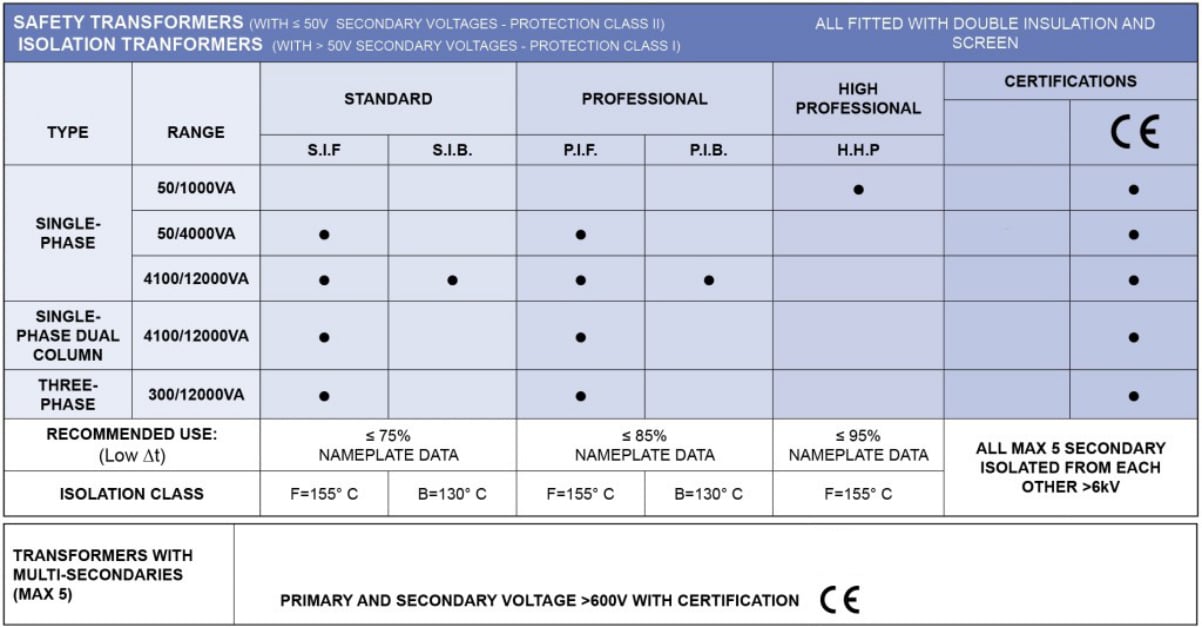

- We can build transformers with multiple secondaries up to 5 outputs (with different voltages and powers on each secondary) to reduce size and costs.

- Input and output voltages are customer-specific.

-

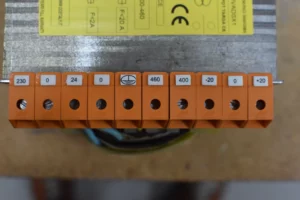

Various types of terminals to choose from depending on the application.

-

Input and output terminal arrangement is customer-specific.

-

Flexible delivery times.

-

Availability to collaborate on new projects

-

Each transformer is equipped with a serial number to identify it with its own test certificate.

-

Testing on each single piece (see quality page)

-

RoHS compliance

-

Products with UL-certified materials for the North American market

Isolation transformers

The two windings of the transformer are separated by a double Galvanic insulation which limits the contacts between live parts and the earth which, in case of failure of the main insulation, can generate dangerous voltages.

Safety transformers

They are isolation transformers used in the power supply of safety low voltage circuits on the secondary <50 V.

Electro-medical equipment (safety and isolation)

We build transformers compliant with the electromedical standard CEI EN60601-1.

With this term we refer to the resistance of the insulating enamel that covers the copper conductors. That is the resistance that the insulating enamel has towards the overheating that can be generated during normal operation. All our transformers are in class F = 155 °.

A single transformer, more windings, more space at low cost

With the advancement of technologies, the challenges for plant designers increase.

O.c.e. , with its multi-output transformers, aims to help its customers with space problems. With our technology, users with different voltages and powers can be powered in a single product. This perspective shows some benefits:

More space available (one transformer, more customized outputs)

Low purchase costs

A copper sheet that is placed between primary and secondary and, its height, can vary depending on the reel used. A yellow / green cable is connected to it. Its task is to reduce distortions, overvoltages and disturbances that are discharged to the ground. This component is mandatory in transformers for the electro-medical sector. All transformers of O.C.E. they have an electrostatic screen regardless of the sector of use.

There are various types of insulation but we can define the most common ones, namely Basic insulation and supplementary insulation.

The first is the basic insulation to divide the live parts from the rest and ensure protection from contacts

The second is an independent insulation that has the task of intervening in the event of a failure of the fundamental insulation.

All of our safety and isolation transformers use double insulation which includes both basic and additional insulation.