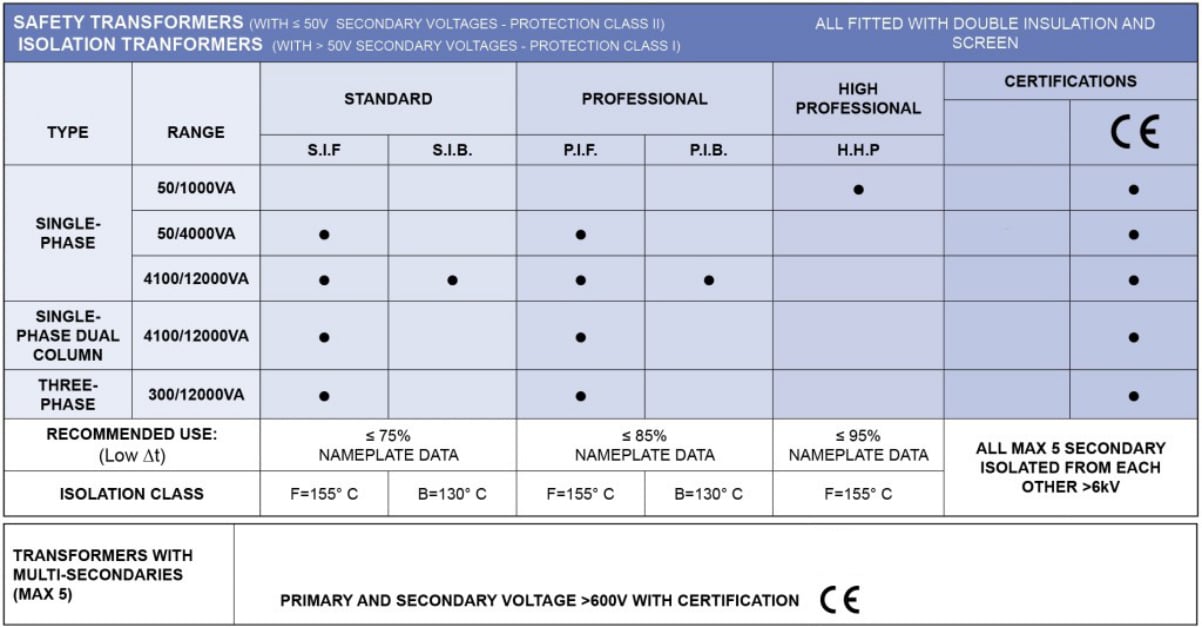

Custom Safety and Isolation Transformers Tailored to Your Needs

We manufacture safety and isolation transformers both in standard versions and fully customized models, designed to order according to the primary and secondary voltage values requested by each customer.

Over time, O.C.E. has introduced advanced technical solutions to ensure increasingly higher quality and maximize customer satisfaction.

Each transformer can be configured with various construction options to perfectly meet the needs of installers, designers, and system integrators.

Custom Design – Total Flexibility for Every Requirement

Thanks to a thorough analysis of our clients’ needs, we have developed an advanced customization method that allows us to reduce delivery times for personalized safety and isolation transformers.

What we can build for you:

-

Multi-secondary outputs up to 5

We manufacture transformers with up to five secondary outputs, each with different voltages and powers, optimizing space and cost. -

Custom voltages

We configure input and output voltages according to customer specifications, ensuring adaptability to various applications. -

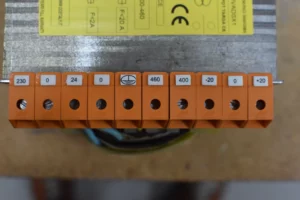

Various types of terminals

We offer a selection of terminals to meet the specific needs of each project. -

Custom terminal arrangement

We adapt the layout of input and output terminals based on customer requests, facilitating installation. -

Flexible delivery times

We manage production schedules to align with your project deadlines. -

Collaboration on new projects

We are available to work together on innovative projects, providing tailor-made solutions. -

Unique serial code

Each transformer is identified by a unique serial code linked to its test certificate. -

Testing on every single unit

We perform rigorous tests on every transformer to ensure the highest quality and reliability. -

ROHS compliance

Our products comply with the ROHS directive, ensuring environmental conformity. -

UL materials

We manufacture transformers using components and materials certified to UL standards, suitable for applications in the North American market or environments with specific requirements.The finished product is not UL certified but is built with materials compliant with UL standards, offering high reliability and technical compatibility.

Isolation Transformers – Reliable Safety

The two windings of the transformer are separated by a double galvanic insulation that limits contact between live parts and earth, which in case of failure of the main insulation, could generate dangerous voltages.

Our isolation transformers ensure safe galvanic separation between primary and secondary windings through double insulation, reducing the risk of hazardous voltages in case of failure.

This protection is essential to:

-

Limit earth leakage currents

-

Prevent dangerous discharges

-

Protect people and equipment

Ideal for electrical panels, automation, and industrial environments, they are available in standard or custom versions, with voltage values tailored upon request.

Safety Transformers – Low Voltage Protection

Safety transformers are a type of isolation transformer designed to supply low voltage safety circuits (SELV), with a secondary voltage below 50 V.

They are used to protect people and equipment in applications where maximum electrical safety is required.

Available in standard or customized versions according to customer needs.

Electro-medical equipment (safety and isolation)

We build transformers compliant with the electromedical standard CEI EN60601-1.

The thermal insulation class indicates the ability of the insulating enamel coating the copper conductors to withstand the overheating generated during the transformer’s operation.

In practice, it defines the maximum operating temperature that the insulation can endure without deteriorating, thus ensuring safety and long-lasting durability of the product.

All our transformers are made with Class F (155°C) materials, ensuring high thermal resistance and reliability even under the most demanding operating conditions.

A single transformer, more windings, more space at low cost

With the advancement of technologies, the challenges for plant designers increase.

O.c.e. , with its multi-output transformers, aims to help its customers with space problems. With our technology, users with different voltages and powers can be powered in a single product. This perspective shows some benefits:

More space available (one transformer, more customized outputs)

Low purchase costs

The electrostatic shield is a thin copper foil placed between the primary and secondary windings of the transformer. Its height may vary depending on the type of coil used.

Connected to ground via a yellow/green wire, this component serves to reduce distortions, overvoltages, and electromagnetic interference, ensuring better signal quality and enhanced safety.

The electrostatic shield is mandatory for transformers used in the medical equipment sector, but all O.C.E. transformers are equipped with it regardless of the application, to guarantee high standards of reliability and protection.

There are different types of insulation, but the most common are basic insulation and supplementary insulation.

Basic insulation serves as the primary barrier that separates live parts from the rest of the system, providing protection against accidental contact.

Supplementary insulation is an additional, independent layer designed to act in case the basic insulation fails, thereby enhancing overall safety.

All our transformers use double insulation, combining both basic and supplementary insulation to offer maximum protection and reliability.